The best solution for toothbrush packaging

Sep 30, 2024When the sun rises, the first thing we do when we open our eyes is to wash our face and brush our teeth. Are you interested in the production and packaging of toothbrushes? Do you want to know how toothbrushes are packaged into various outer packaging? If you are interested in the packaging of toothbrushes, you must not miss this article.

The packaging of toothbrushes corresponds to different packaging styles for various needs. Common packaging includes simple bags, paper card packaging, plastic boxes and other different methods. In order to stimulate customers' consumption power, manufacturers selling toothbrushes have also launched a box of multiple different colors of packaging, so as to attract customers to buy with cheapness and large quantities. Because toothbrushes are our daily necessities, more and more people are engaged in the toothbrush packaging industry, and toothbrush packaging is inseparable from pillow packaging machines. Next, I will introduce you to the most perfect packaging solution for toothbrush packaging, using pillow packaging machines for packaging.

Working principle of pillow packaging machine

The pillow packaging machine works differently from other packaging machines. It is mainly composed of packaging film conveying, material conveying, sealing device, cutting device and other control systems. When packaging starts, the packaging film will start working first. First, the packaging film will be pulled out and form a relatively flat packaging film after passing through the guide roller. At the same time, we need to transport the toothbrushes to be packaged in an orderly manner through a vibrating plate or a conveyor belt to the packaging position and wait for packaging. When the toothbrush reaches the set position, the film will start to wrap the toothbrush, and the two sides and front and back of the film will be sealed by heat sealing or other methods, and cut according to the packaging length you set, so that the outer packaging of the toothbrush is ready for sale.

Notes on toothbrush packaging

Material arrangement and sorting

(1) When we need to pack toothbrushes, we need to place them in an orderly manner so that they can be packaged by the machine. We need to confirm whether the toothbrush head and toothbrush handle are in a horizontal direction. If you need to use a machine to achieve this function, you can customize a combing device to replace manual operation.

(2) The quantity needs to be controlled according to the packaging requirements. Some manufacturers like to sell toothbrushes for family use, which requires a large number of toothbrushes. If it is a single toothbrush or a package specifically for hotel use, it is a small amount of packaging. It depends on your needs. The pillow packaging machine can meet all needs. Whether it is multiple or single toothbrushes, the distance between the toothbrushes needs to be guaranteed to avoid multiple toothbrushes in one roll or the roll film being wasted.

Selection of packaging film

(1) Most toothbrush packaging is done with paper cards, with transparent plastic on the front and paper cards on the back for product introduction. The transparent film material allows consumers to clearly see the appearance, shape, quality and other information of the toothbrush, so it is very important to choose the right packaging method when packaging the toothbrush.

(2) When packaging the toothbrush, the machine needs to be debugged to ensure that the tension of the film is just enough to cover the surface of the toothbrush to avoid affecting the subsequent packaging and causing the risk of being too tight or too loose, unsightly and leaking.

Advantages of pillow packaging machine

(1) Three servo control, automatic detection of product length and cutting, the operator does not need to adjust the unloading work, saving time and film.

(2) Human-machine operation, parameter setting is convenient and fast.

(3) Fault self-diagnosis function, fault display is clear at a glance.

(4) High-sensitivity photoelectric color mark tracking, digital input cutting position, making sealing and cutting more accurate.

(5) Temperature separate PID control, suitable for various packaging materials.

(6) Positioning shutdown, no sticking knife, no waste of packaging film.

(7) All controls are realized by software, which is convenient for function adjustment and upgrade.

(8) Automatic feeding system, feeds cotton swabs into the chain conveyor one by one.

(9) High-speed rolling and cutting, with an output of 250-300 swabs per minute.

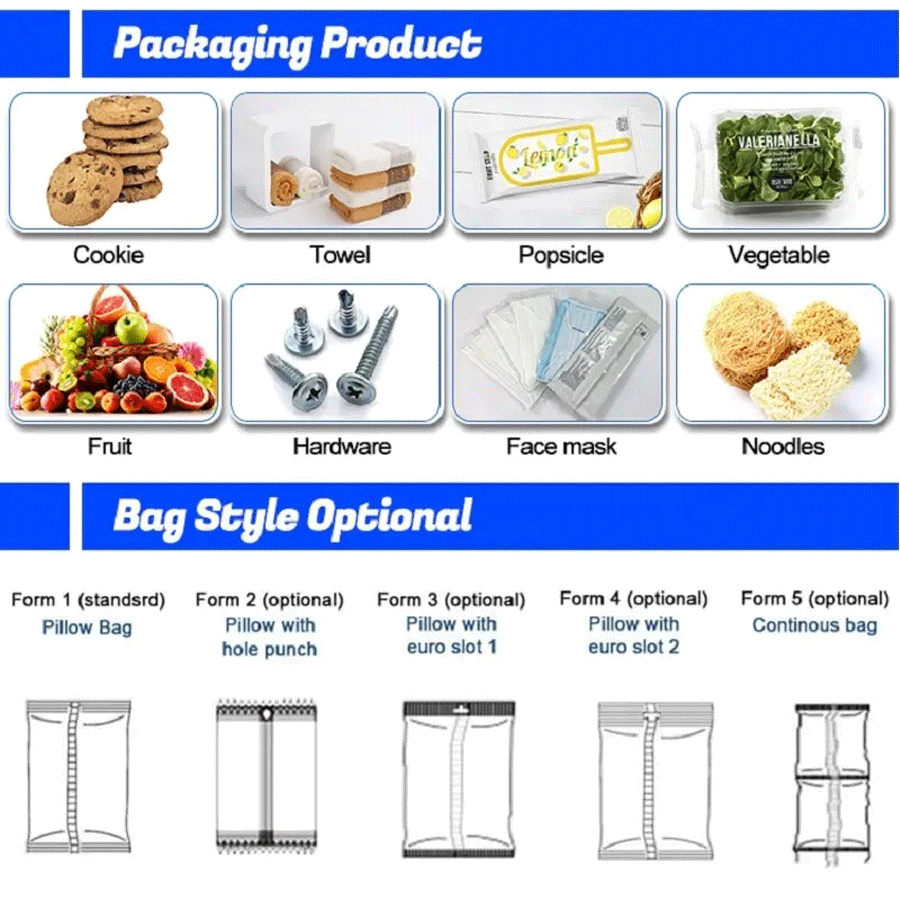

Application of pillow packaging machine

Although this packaging machine is different from the vertical packaging machine in packaging, the scope and objects that this machine can package are wider than the vertical packaging machine.

(1) Food industry

Applicable to packaging bread, candy, biscuits, noodles, cabbage, vegetables, fruits, etc.

(2) Daily necessities industry

Applicable to packaging toothbrushes, towels, toothpaste, facial tissue, diapers, soap, etc.

(3) Pharmaceutical industry

Applicable to ointments, gauze, cotton balls, capsules, etc.

(4) Industry

Applicable to small hardware parts, electronic components, etc.

The above article introduces the best solution for toothbrush packaging in detail. Pillow packaging machine is the best solution for toothbrush packaging in various industries. It provides different packaging solutions in different industries and is deeply loved by people.