What is a vertical form fill seal machine (VFFS)?

Sep 18, 2024Nowadays, all kinds of items that can be packaged in containers or bags in our daily use are inseparable from packaging machinery. Now packaging machinery is becoming more and more common in our lives. Today I would like to introduce a packaging machine to you - vertical filling and sealing machine (VFFS).

What is a vertical form filling and sealing machine?

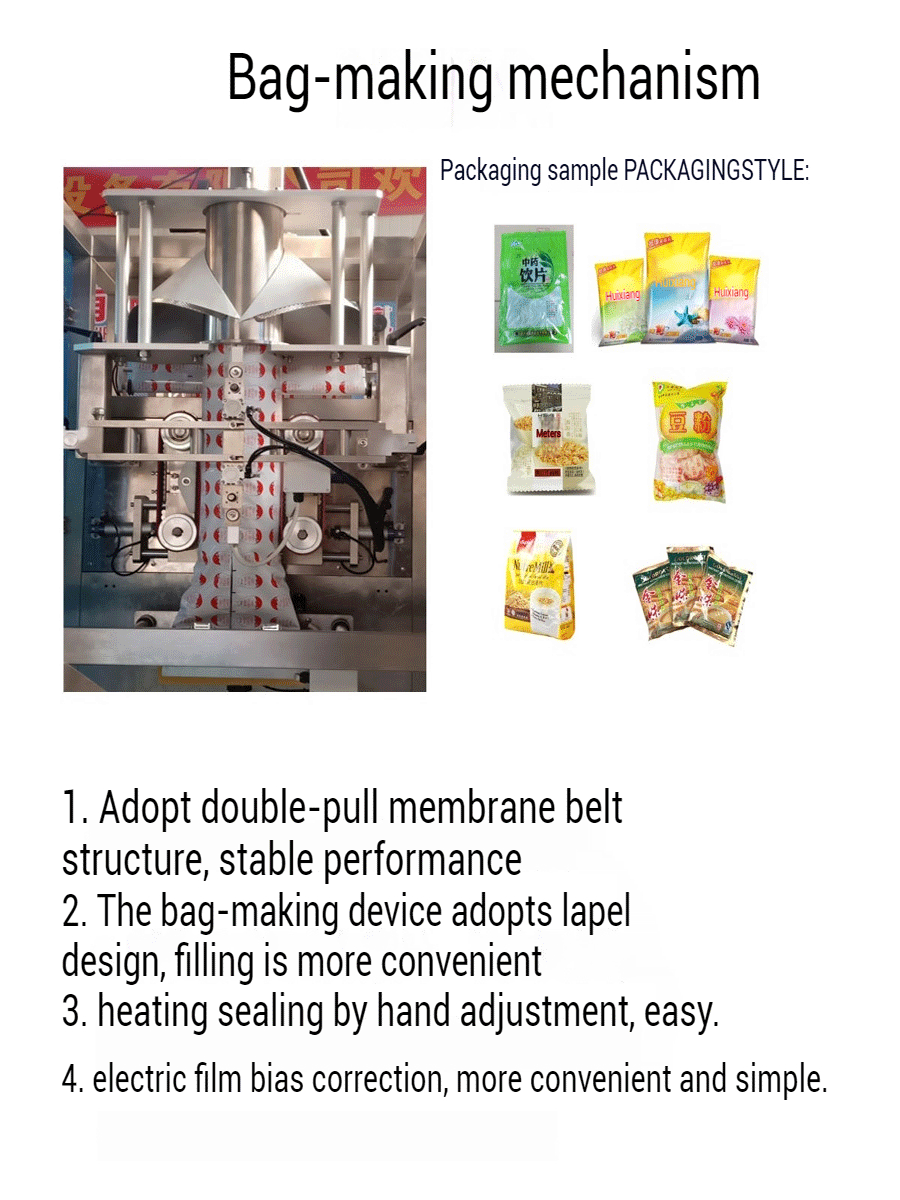

Vertical form filling and sealing machine (VFFS) is mainly used to package all the products that need to be sold in packaging. It can package everything. This machine can produce various packaging styles for you. You can choose your favorite sealing method to design, such as pillow bags, square bags, pin bags, zipper bags, back seals and other bag styles. These sealing methods depend on the characteristics and shape of your products and your design requirements for the products. In these bags, you can design, such as product information, introduction, production date, etc., to attract customers and increase purchasing power.

Working principle of vertical filling and sealing machine

The vertical filling and sealing machine is roughly divided into two parts, filling and sealing, as its name suggests. Regardless of whether the packaged materials are powders, granules, liquids, pastes and other different materials, their working principles are the same, and they all need to go through these two working steps. Next, I will introduce its working principle to you in detail.

1. Feeding

When the machine needs to package, the first step is to have materials to package. This is also one of the few parts of the packaging machine that requires manual participation. We need to put the materials to be packaged in the filling part of the machine-the hopper. This needs to be customized according to the characteristics of the materials you package and the requirements of filling. If it is a powder or granular material, it will be placed in the hopper part, but due to the nature of the powder that is easy to fly dust, a protective cover will be installed to prevent flying powder. For materials like liquids or pastes, another pressure device is used for feeding. If the material is easy to solidify or needs to be mixed, the agitator or insulation hopper of the feeding device will be customized for you.

2. Weighing

When the machine senses the material, you can set the weight you want to package on the panel of the machine. In this way, the control system will weigh according to your requirements through vibration or air pressure pump, which improves the accuracy of weighing, avoids the error of manual operation, and ensures the precise zero error of filling, which is impossible to do manually.

3. Unloading

After the packaging machine is set up through feeding and weighing, it will cooperate with the roll film to unload the material according to the weight of a package you set. At this time, the material will enter the roll film through the former and wait for the machine to seal.

4. Sealing

Usually, packaging machines use heated aluminum blocks to seal the roll film to meet the packaging requirements. The temperature of the seal is increased by heating the temperature and the roll film is melted by pressure. Under the action of pressure, the molten plastic film fuses with each other and cools and seals tightly. Some seals are pneumatic and need to be connected to an air compressor. This can be customized according to your needs. If you want to package liquid but don’t want there to be any air in the bag, you can customize the iron seal to achieve it.

The above is the working principle of the vertical filling and sealing machine (VFFS). Feeding, weighing, and unloading belong to the filling steps, and sealing is the working principle of the vertical packaging machine. However, this is inseparable from the control system of the packaging machine to operate to achieve such a packaging effect. This is the embodiment of the intelligence and precision of the packaging machine. The vertical filling and sealing machine can quickly and efficiently fill materials into containers and seal them through precise filling and sealing operations to ensure product quality and safety.

You can click on the picture below to jump to the machine you are interested in. These machines are all vertical filling and sealing machines, but the purpose and materials of packaging are different. You can choose the machine you like to learn more.

Advantages of vertical filling and sealing machine

Through the above introduction, I think everyone has a certain understanding of this machine. I would like to introduce the advantages and strengths of this machine to you again, hoping to help you understand and know this machine better.

1. Applicable to a variety of scenarios

The vertical structure design takes up less space, which is suitable for small entrepreneurs and suitable for sites of different sizes to improve space utilization.

2. High packaging efficiency

It has a high degree of automation, can complete filling and sealing operations quickly and continuously, reduce labor costs, and is equipped with a high-speed filling system and precise sealing device, which can reach nearly 100 packages per hour (depending on the material and gram weight)

3. Accurate packaging

It has an accurate weighing system for weighing, controls the filling accuracy of the material to ensure the accurate gram weight of each packaging bag, saves you costs and avoids gram weight problems affecting sales.

4. Wide range of applications

The vertical filling and sealing packaging machine integrates filling and sealing to save you money. It can be customized according to the material you want to package, and can be applied to many different types of materials, including liquids, powders, granules, etc.

(1) Beer, milk, milk powder, seasoning, biscuits, candy in the food industry

(2) Fertilizer granules, powder preparations, nutrient solution in agriculture

(3) Various powdered and granular raw materials in the chemical industry

(4) Washing powder, laundry detergent, toothpaste in the daily chemical industry

Vertical filling and sealing machines can also adapt well to packaging containers of different specifications and shapes, such as plastic bags, plastic bottles, paper boxes, etc., and have strong versatility and compatibility.

5. Simple and easy to learn

The control system is usually designed to be simple and easy to understand. Operators can start operating after simple training, which reduces the requirements for the operator's skill level.

Vertical filling and packaging machine is an efficient packaging equipment suitable for filling and sealing of liquids, powders, granules and other materials. With its high work efficiency and reliable quality, it is deeply loved by people and provides new solutions for the packaging of various materials. I hope this article can help you.