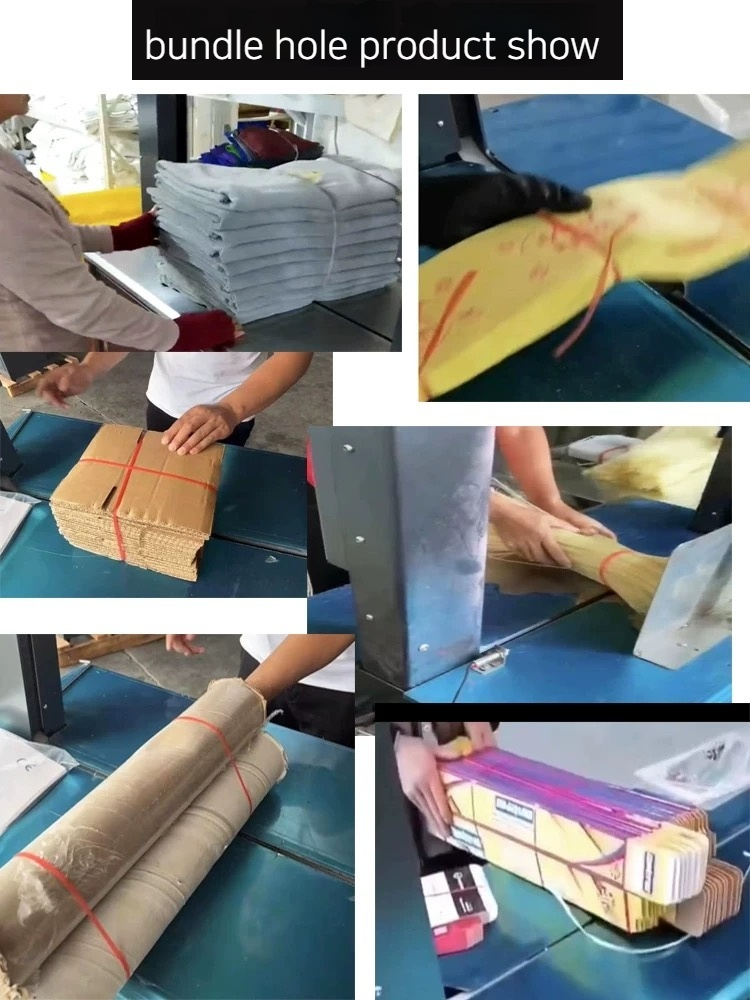

The Automatic Strapping Machine is a productive solution for most polypropylene strapping tasks. This automatic arch strapping machine features an "Auto Feed" feature that automatically feeds the polypropylene strapping into the arch and prepares it for each application. The "Auto Positioning" system automatically and efficiently positions the polypropylene strapping for each cycle

Item NO.:

ZLDBZ001Shipping Port:

XiamenLead Time:

7-14dayCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionEmail: Molly@xmlk-machine.com

Whatsapp/Wechat: +8618150150881

Function:

(1) The machine adopts Taiwan technology to ensure stable and trouble-free packaging. The table is driven by a power belt, which is suitable for small items packaging. Photoelectric sensor positioning is adopted, and the packaging position can be set arbitrarily.

(2) The machine has automatic threading, automatic heat sealing, and automatic cutting functions, which can adapt to products of different sizes. The standard machine can supply low parts at any time, and can be customized according to the user

Function ejects missed belt cycles and resets the equipment.

(3) User-friendly controls allow operators to choose between panel-mounted controls, foot pedals or tabletop ball switches. Actual production will vary according to packaging size, chute size and operator flexibility.

(4) 220V, 1-phase/3-phase power is required. Polypropylene strapping is sold separately.

| weight capacity | 80kg |

| Binding speed | And 40-lane / min |

| Bale tightforce | 0-60kg |

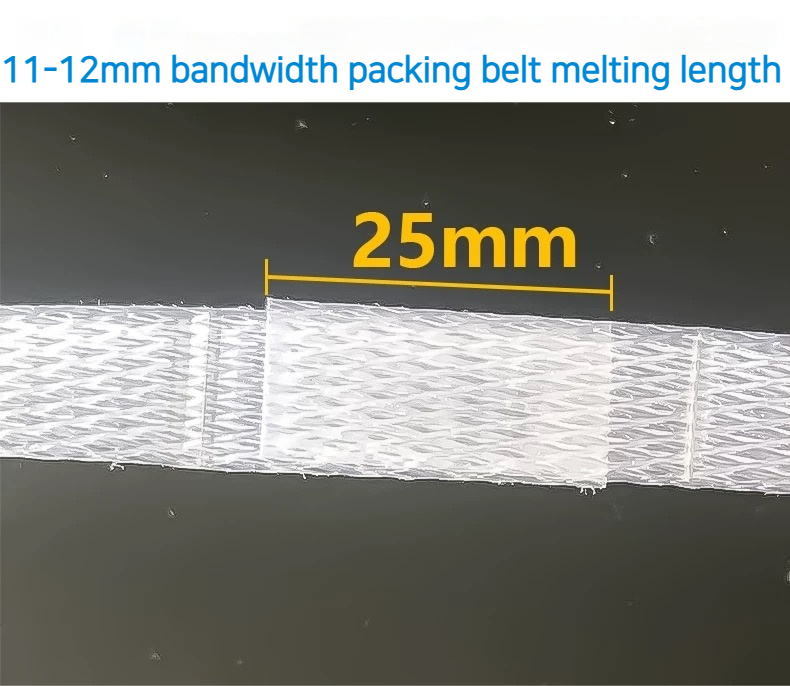

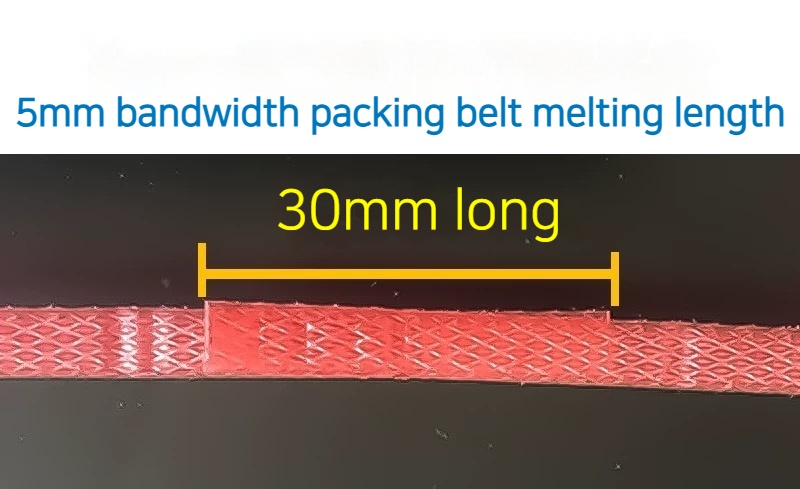

| Binding belt | Polypropylene thin, 12mm wide and0.5mm~0.8mm thick |

| Working tableheight | 750mm |

| Standard frame size | 800mm wide * 600mm high |

| External size | 1350mm*620mm*1450mm |

FAQ

A: Yes, we can customize the machine according to your requirements.