Features:

(1) All the Electronic components adopt international famous brand excluding motor, the motor use regular domestic brand.

(2) The raw material of the products adopts stainless stee

(3) Mitsubishi PLC control system

(4) English panel

(5) Noiseless stepping motor to improve steady working condition and decrease vibrator and noise.

(6) Can get a perfect pictures when the packing material with color code.

(7) This machine is easy to operate and maintain.

(8) This machine can finish pulling, forming, fulfilling, measuring, sealing, cutting, printing automatically.

Item NO.:

BZ006Product Origin:

ChinaShipping Port:

XiamenLead Time:

7-14dayCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionEmail: Molly@xmlk-machine.com

Whatsapp/Wechat: +8618150150881

Video of machine working

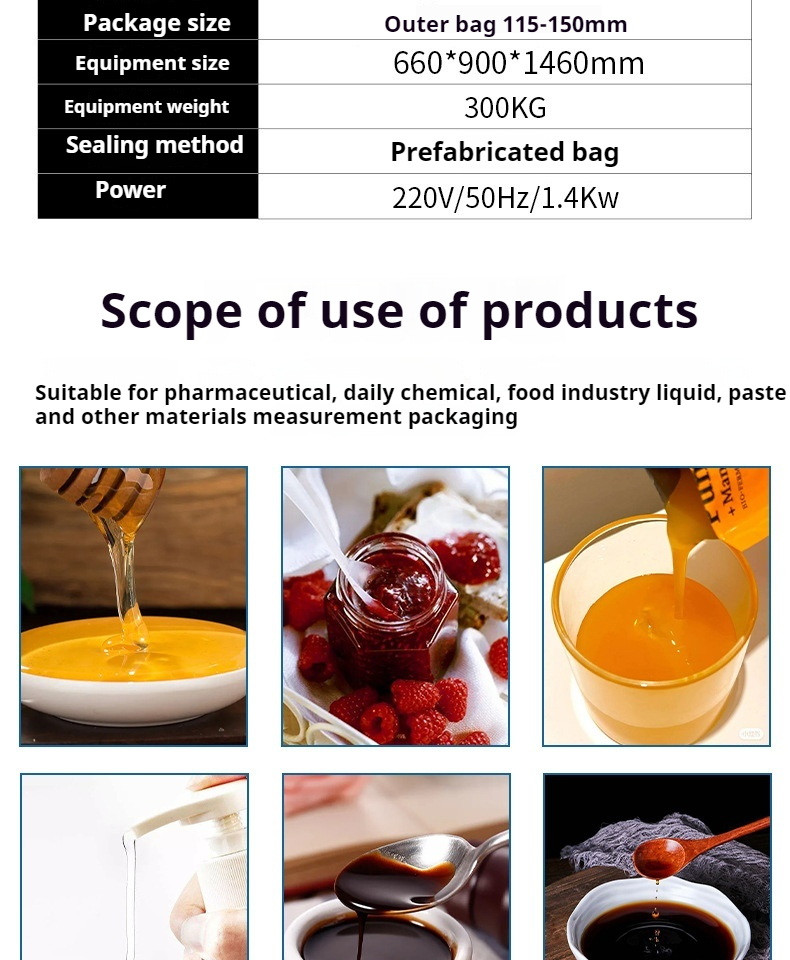

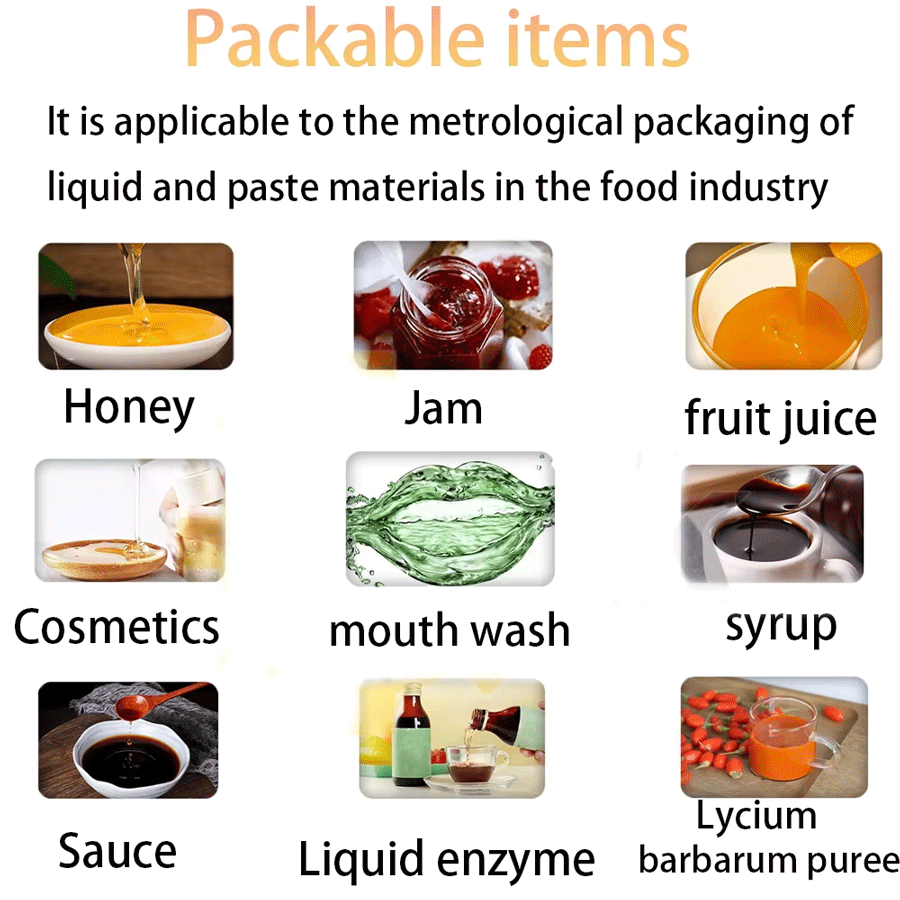

Multifunctional stand-up bag packaging machine application

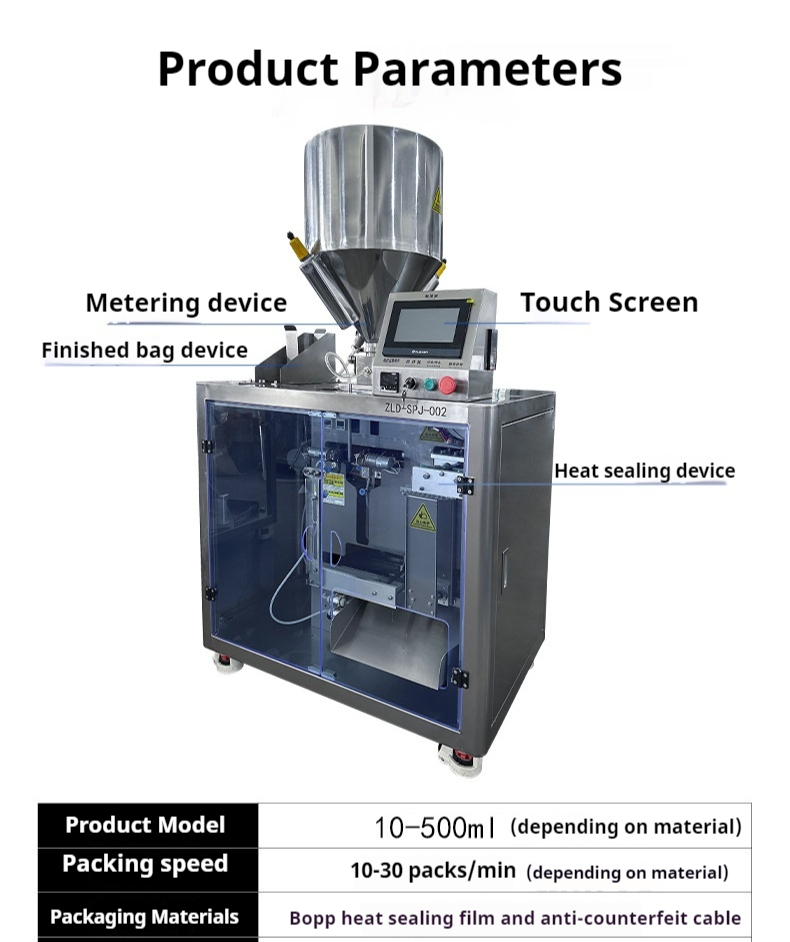

Filling machine fully automatic flat bag hot paste ketchup mayonnaise filling pre-made bag horizontal packaging machine

(1) Except for the motor, all electronic components are internationally renowned brands, and the motor is a domestic regular brand.

(2) The raw materials of the product are made of stainless steel, and the parts that contact the product or packaging bag are made of stainless steel or other materials that meet food hygiene requirements to ensure the hygiene and safety of the food.

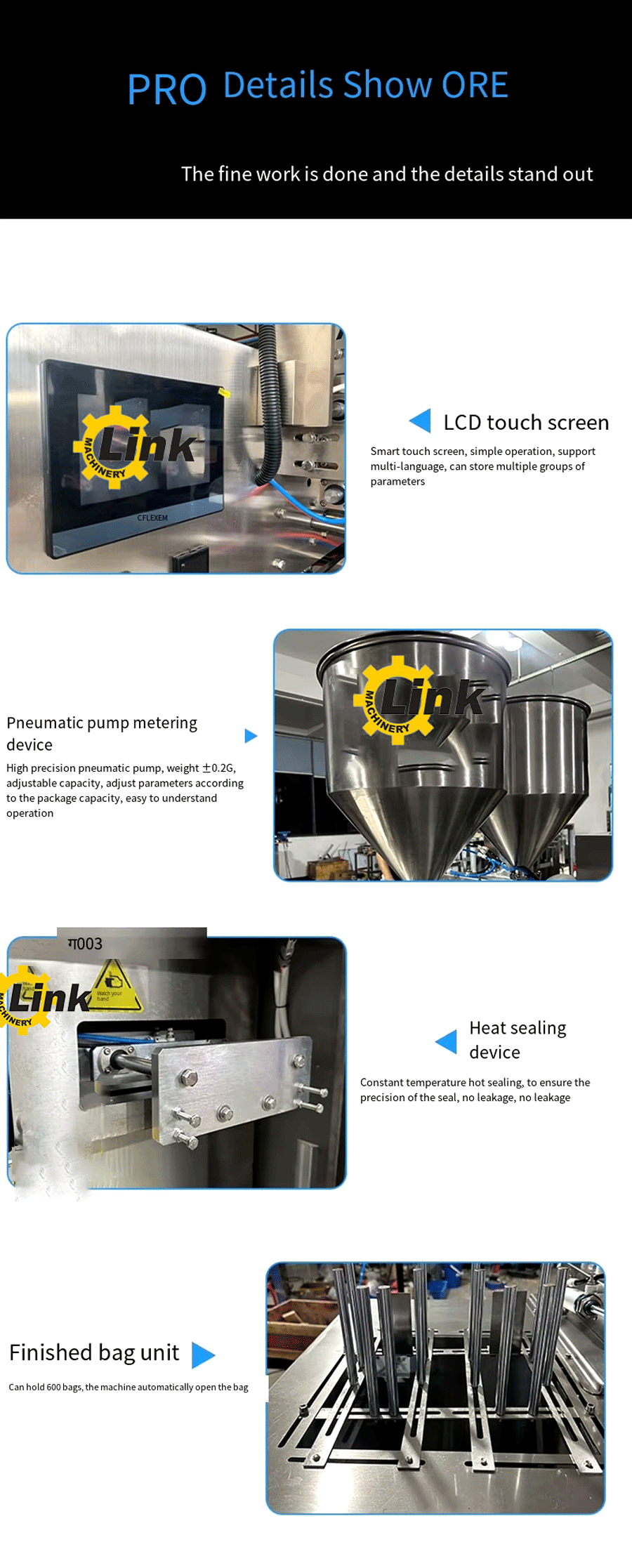

(3) Mitsubishi PLC control system, English panel; the machine is small in size, light in weight, and not limited by space.

(4) Noiseless stepper motor, improves the working state stability, reduces vibration and noise. Four processes, low failure rate, high stability, fast production speed, easy combination, one-button operation, start-up and use, no professional operation required.

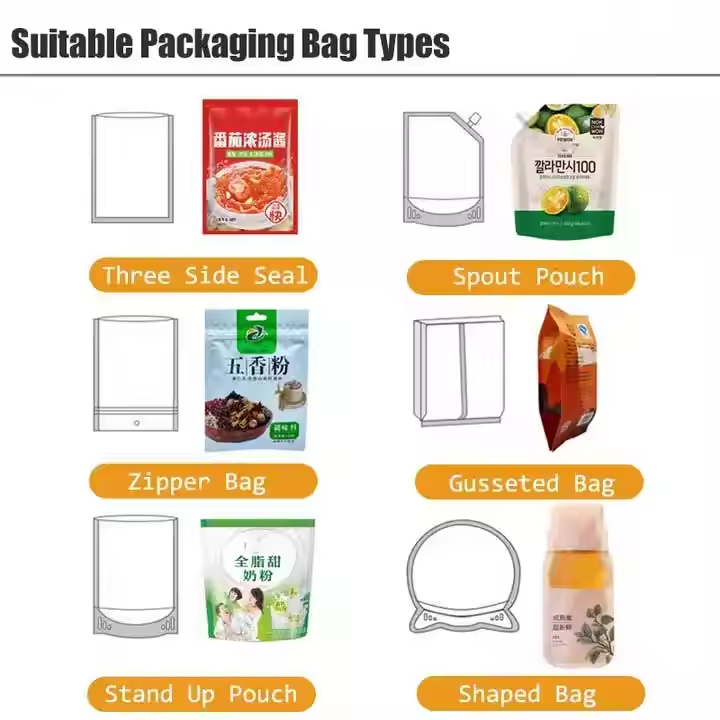

(5) Perfect image can be obtained when the packaging material is with color code. Different pockets can be replaced without adding accessories to adapt to bags of various shapes.

(6) This machine can automatically complete traction, forming, filling, metering, sealing, cutting, printing and other actions. Automatic detection: no bag or wrong bag opening, not full, not sealed, the bag can be reused to avoid wasting packaging materials and raw materials.

(7) Replacing different feeders can package solids, liquids, thick liquids, powders, etc. Fully customizable service, can replace or upgrade other brands of electrical configurations, logo customization, etc. according to customer needs.

FAQ