Item NO.:

BZ006Product Origin:

ChinaShipping Port:

XiamenLead Time:

7-14dayCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionEmail: Molly@xmlk-machine.com

Whatsapp/Wechat: +8618150150881

Large capacity liquid and semi-fluid feeding mechanism

Application

Suitable for packaging liquids, pastes, mixed sauces, such as chocolate sauce, hot pot base, ketchup, chili sauce, etc.

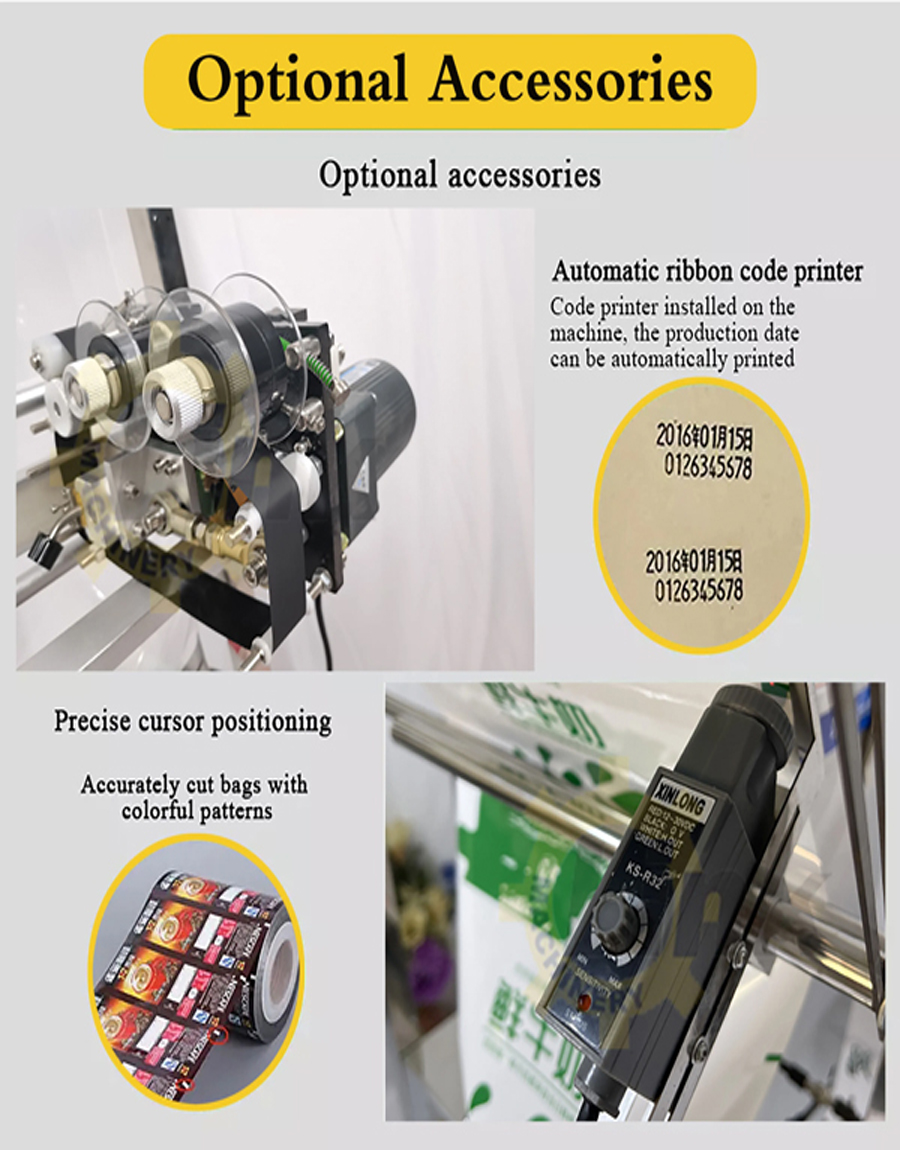

Optional equipment

Vertical agitator

Horizontal agitator with material barrel

Diaphragm pump

Cursor

Coder

Machine Features

With acrylic protective cover, 7-inch touch screen, three-side seal or back seal, industrial-grade PLC control system, whole machine 304 material, independent electric control box, independent temperature control, horizontal sealing mechanism is copper material coated with Teflon anti-sticking, two horizontal sealing mechanisms, high-power clamping and pulling mechanism, feeding mechanism

Features and Advantages

1. Large-capacity conveying: It can meet the large-scale conveying needs of liquid and semi-fluid materials in large-scale production and improve production efficiency.

2. Stable and reliable: It adopts a reliable pumping system and pipeline connection to ensure the stability and continuity of material conveying and reduce production losses caused by conveying interruptions.

3. Precise control: The pumping flow and pressure can be accurately adjusted through the control system to meet the requirements of different production processes.

4. Strong adaptability: It is suitable for various liquid and semi-fluid materials, including high viscosity, corrosive, and particle-containing materials. The appropriate pump and pipeline material can be selected according to the properties of the material to ensure the long-term stable operation of the feeding mechanism.

5. High degree of automation: It can be automatically integrated with other equipment on the production line to achieve unattended automatic feeding, reduce labor costs, and improve production safety.

|

Packing range |

100-500/200-1000/200-2000ml |

|

Power |

700W |

|

Dimensions |

95*140*220cm |

|

Packaging size |

136*114*165cm |

|

Packing speed |

1200-1500 (pcs/h) |

|

Bag width |

less than or equal to 200mm |

|

Power requirement |

air compressor is required |

|

Air compressor exhaust volume |

0.36m³/min |

|

Air compressor air storage capacity |

≧70 L |

Large-capacity liquid and semi-fluid feeding mechanism

Juice, honey, ketchup, peanut butter, garlic sauce, milk, condensed milk, shampoo, gel, lotion, emulsion, liquid detergent, liquid

Soap, oil, cream, glue...

With acrylic protective cover

Date batch printer

7-inch touch screen

Industrial-grade PLC control system

Horizontal sealing mechanism is copper material coated with Teflon anti-sticking

High-power clamping and pulling mechanism, feeding mechanism