Machine Introduction

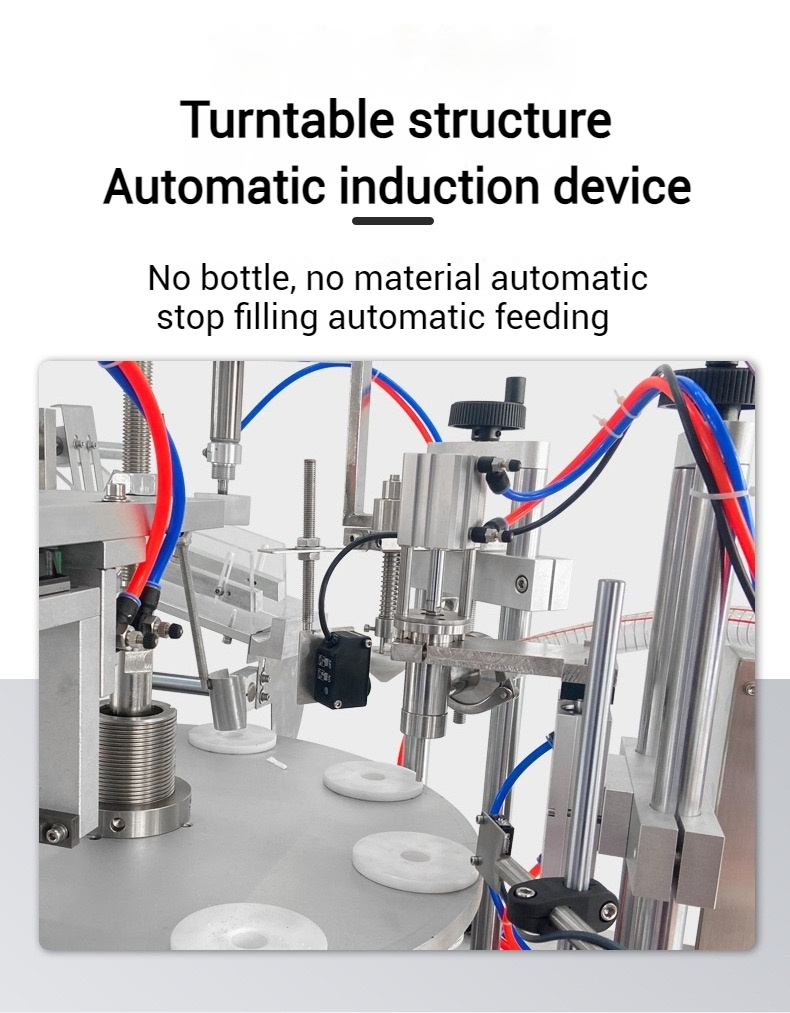

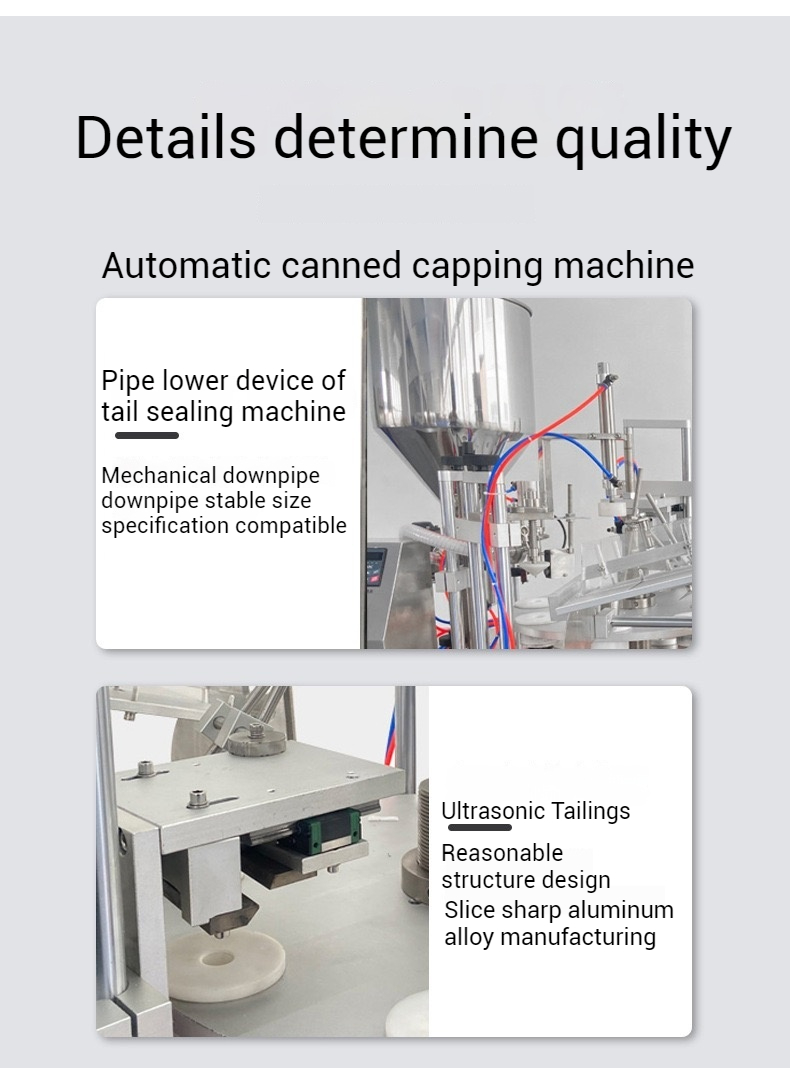

The automatic ultrasonic tail sealing machine is a high-quality, high-performance liquid and paste container filling and sealing packaging machine. The machine adopts a series of functions such as manual tube placement, automatic color mark detection, automatic filling, automatic tail sealing, automatic cutting, and automatic output of finished products. The overall operation of the machine is simple and perfect, which helps enterprises improve production efficiency and reduce labor intensity. It is the preferred equipment for improving packaging grade.

Item NO.:

BZ003Product Origin:

ChinaShipping Port:

XiamenLead Time:

7-14dayCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionEmail: Molly@xmlk-machine.com

Whatsapp/Wechat: +8618150150881

Machine working video

Main functions:

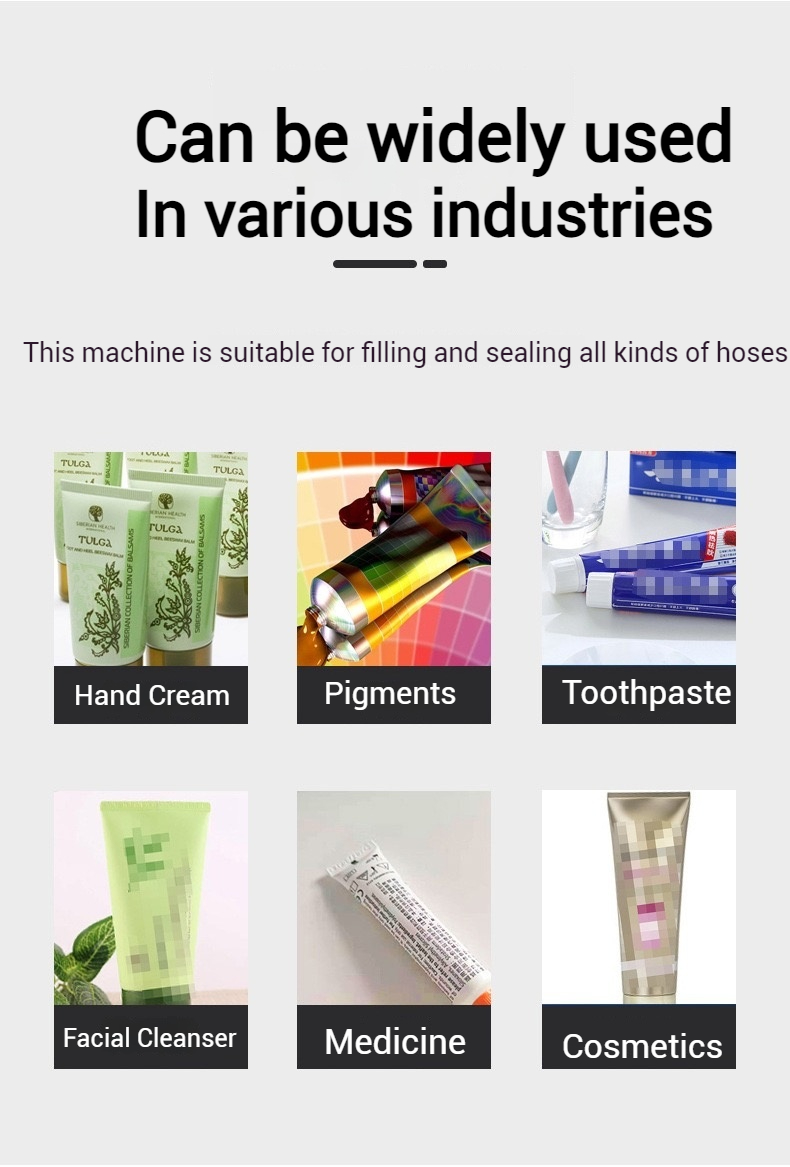

Applicable to: filling and sealing of various plastic hoses or aluminum-plastic tubes for fluids in the food, medicine, cosmetics, chemical and other industries.

Features

1. Intelligent automatic frequency tracking system, which can automatically identify the vibration frequency of the ultrasonic system, thereby effectively protecting the mold. Large output, low noise, stable performance and long life.

2. Replace the traditional welding or bonding process, low cost, clean and pollution-free, and does not damage the plastic tube.

3. High welding strength, good sealing performance, the strength of the welding area is the same as other areas of the plastic.

4. Stable welding process, easy operation and convenient maintenance.

5. Precision IC control circuit, automatic overload protection system.

6. Adopt PLC controller, easy operation, automatic protection system to avoid damage caused by improper operation.

7. Four-point balance adjustment, easy to adjust the welding head.

8. Aluminum/titanium radial pole, sonic wave, strong stability.

9. There are 3 positions for tube loading to avoid tube vacancy.

10. Pressing the cone on the directional position of the tube can ensure that the tube is round.

11. The filling volume can be easily adjusted.

12. Sealing and cutting are both in different positions to avoid burrs.

13. Automatic unloading, finished products can be unloaded to the conveyor.

14. Cold water circulation is installed in the rear mold to ensure the sealing quality under high production conditions.

15. Stepper motor is used for orientation, and the speed can be adjusted to improve accuracy.

16. The machine is equipped with Airtac cylinder and Airtac solenoid valve, with stable performance.

17. Automatic tube feeding, filling, orientation, sealing, code printing, cutting.

| Model | Fully automatic sealing machine with upper tube |

| Voltage | Single phase 220v50HZ |

| Power | 2.6KW |

| Filling range | 5-50ml 10-100ml 30-300m1 (optional) |

| Filling error | 士1% |

| Productivity | 10-20 pieces/minute |

| Sealing diameter | 10-50 mm |

| Hose height | 50-200pj |

| Working air pressure | 0.4-0.6 MPa |

| Gas consumption | 0.38m3/min |

FAQ