Performance & Feature:

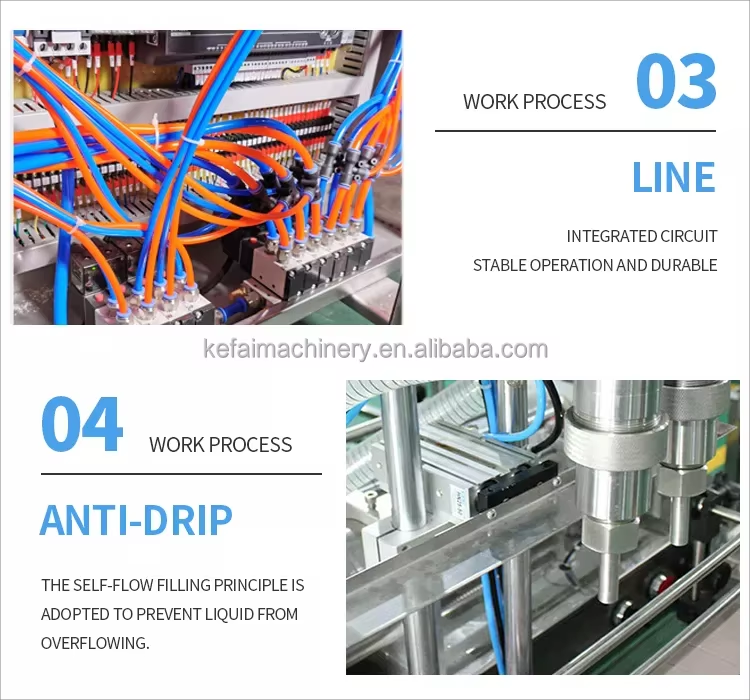

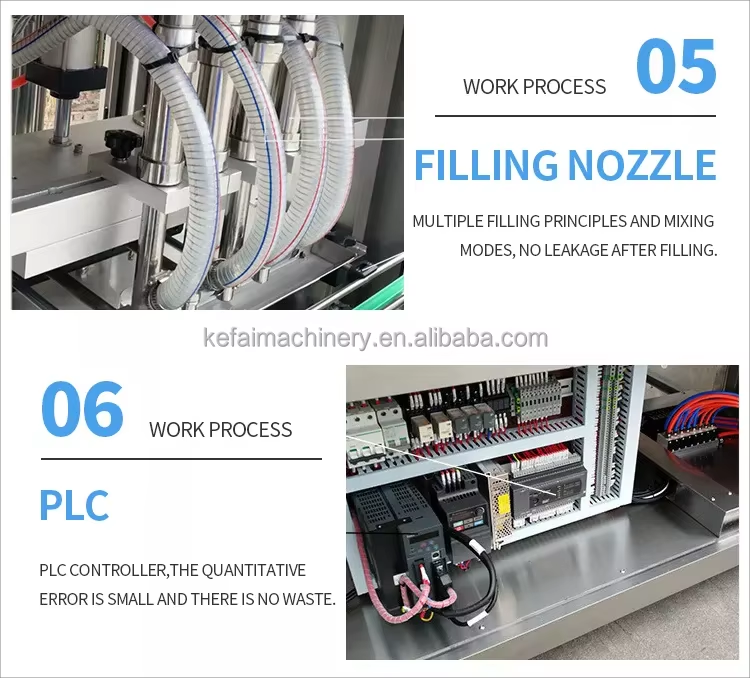

1.the use of advanced man-machine dialogue touch screen,the operation data can be adjusted storage,fault display.

2.Servo drive,digital filling volume adjustment.

3.Precision stainless steel piston cylinder processing technology to ensure accurate filling consistent,so that the seal is not easy to wear long-term operation.

Item NO.:

BZ005Product Origin:

ChinaShipping Port:

XiamenLead Time:

7-14dayCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionEmail: Molly@xmlk-machine.com

Whatsapp/Wechat: +8618150150881

Paste filling machine + automatic capping machine

The bottle sorter arranges the bottles in a row and then enters the dispensing tray position in turn. After passing through the gap of the dispensing tray, when the bottle stops, the filling head falls into the bottle for filling, filling 2 bottles each time. The dispensing cover plate moves intermittently. Every time the turntable rotates through 2 stations, 2 bottles are sent forward, and then stop to enter the gap of the dispensing cover plate. The caps are arranged in a row by the electromagnetic oscillation hopper, and all the mouths enter the dispensing cover track. The lower mouth of the capping track is directly opposite to the center of the gap of the dispensing cover plate. After the bottle enters the gap of the dispensing cover plate, it rotates with the dispensing cover plate, so that the bottle mouth of each bottle is taken away at the lower end of the bottle cap track and the bottle mouth is covered; when the bottle with a cap enters the sealing position with the rotation of the dispensing tray, the sealing seat descends, tightens the bottle cap and the bottle mouth, and the sealed bottle is sent into the bottle hopper through the rotation of the dispensing tray.

FAQ