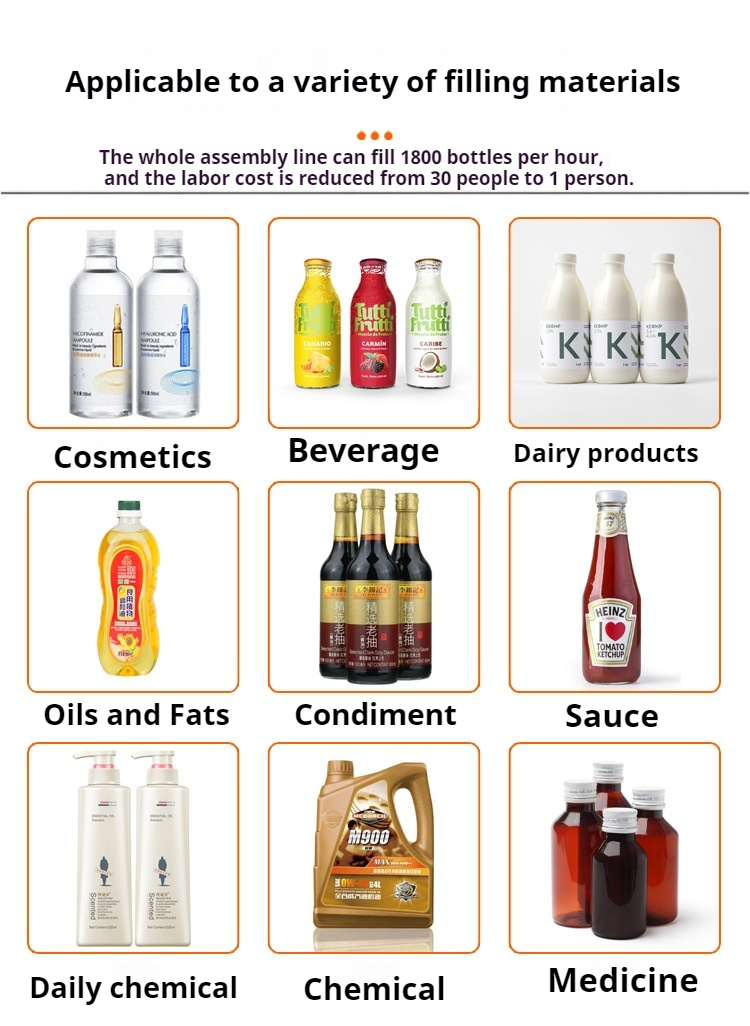

This series of liquid filling machines are suitable for daily chemicals, food, oils, pesticides and other industries, and can fill different types of liquid products.

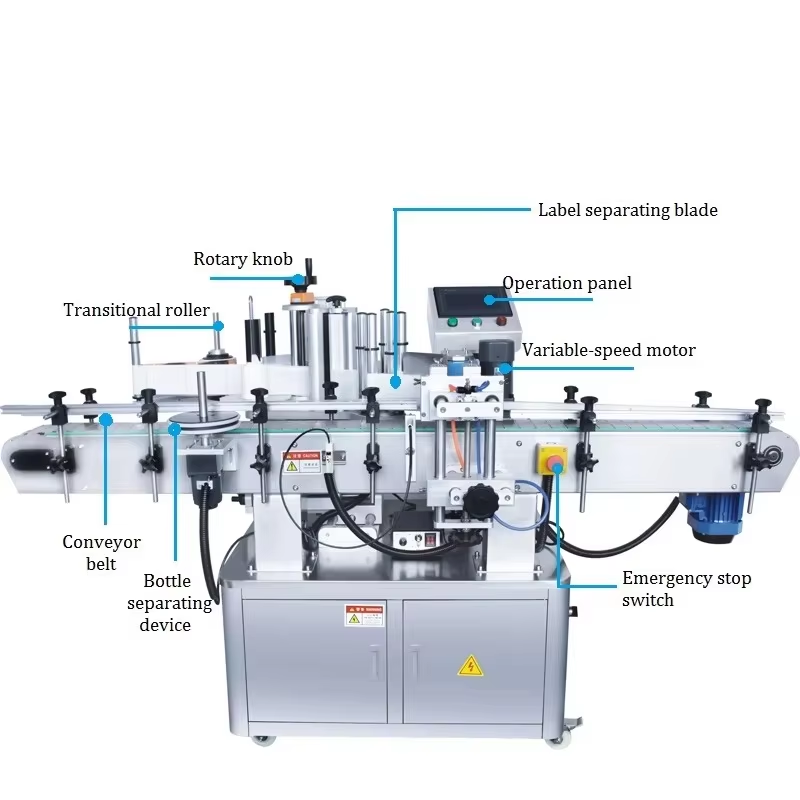

This machine is composed of a bottle unscrambler + horizontal paste filling machine + automatic capping + automatic capping machine. We are a manufacturer specializing in the production of automatic bottle unscramblers. We produce a variety of automatic paste filling machines for you to improve your production efficiency and reduce your labor costs. One machine can achieve all

Item NO.:

BZ002Product Origin:

ChinaShipping Port:

XiamenLead Time:

7-14dayCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionEmail: Molly@xmlk-machine.com

Whatsapp/Wechat: +8618150150881

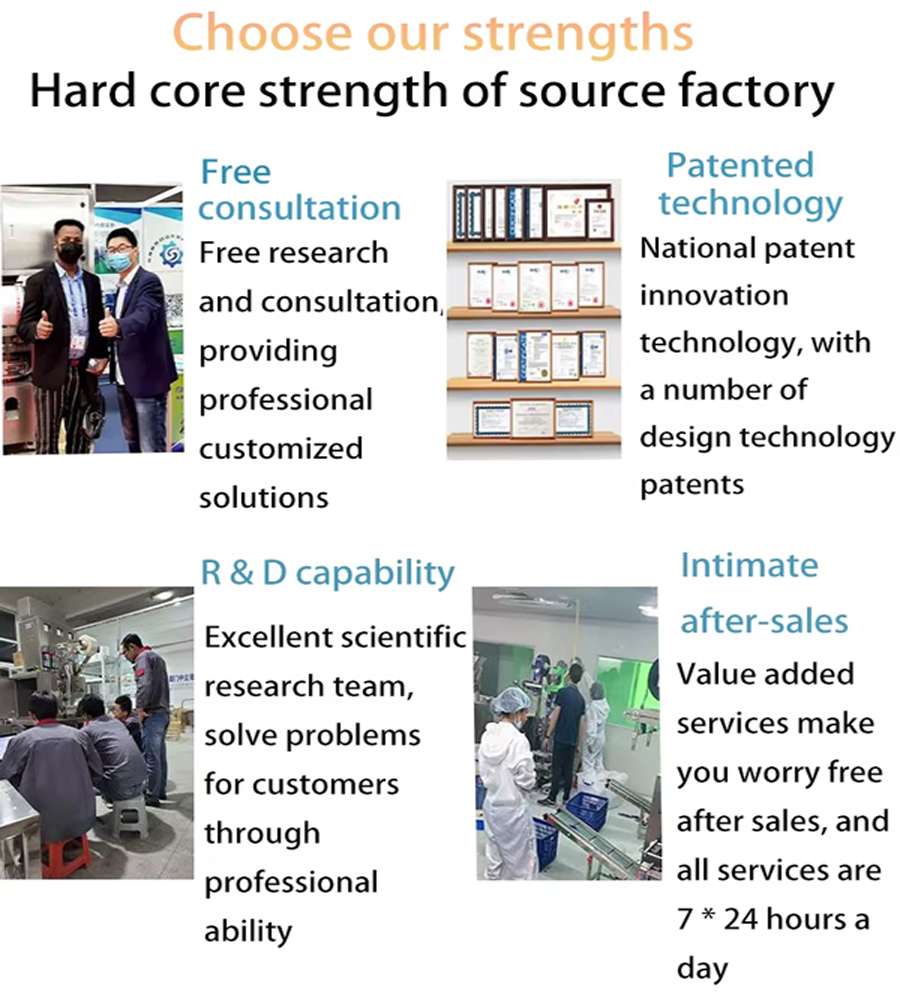

Features

Piston-type linear filling with high precision filling, easy installation and commissioning, cleaning and maintenance is simple, no dripping and so on. Contact with the material are made of 304 stainless steel (custom 316 stainless steel), all stainless steel rack, with clean and tidy,beautiful and beautiful appearance and so on. Using Taiwan PLC control, touch screen man-machine interface, the German sick light eyes,Germany FESTO, Taiwan Air Tac and other imported components, so that the filling machine has a stable performance, flexible operation of the outstanding performance.

FAQ